Products

- Core Preparation

- Routine Core Analysis

- Special Core Analysis

- Reservoir Stimulation

- EOR

- IFT Measurement

- Fluid Sampling

- PVT

- Pump

- Drilling Laboratory

- Petroleum Laboratory

- Aniline Point Measuring Device

- Cloud Point Measuring Device

- Copper Corrosion Measuring Device

- Distillation Apparatus for Petroleum Fluids

- Ductility of Bituminous Materials Measuring

- Flash Point Measuring Device

- Ostwald’s Viscometer

- Penetration of Bituminous & Lubricating Grease Materials Measuring Device

- Pour Point Measuring Device

- Reid Vapor Pressure Measuring Device

- Saybolt Viscometer

- Smoke Point Measuring Device

- Softening Point of Asphalts & Tar Pitches Measuring Device

- Fluid Laboratory

Our group is among the knowledge-based enterprise pioneers in petroleum industry.

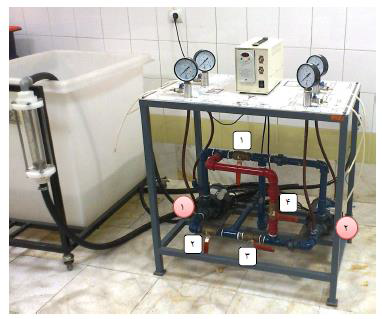

General Core Flooding

The CF evaluates and optimizes oil recovery, based on different injection protocols and fluid, such as miscible and immiscible gas injection, surfactant injection, polymer injection and etc. This device tolerates a maximum pressure and temperature of 400 bar and 100 °C respectively, under unsteady state conditions at confining pressures up to 400 bar. One of the transfer vessels is a miniature type that can be used for rinsing the lines by filling them with toluene or other solvents. (E20: in addition, this miniature transfer vessel can be used for chemical or microbial flooding which the injected slug is small).

| Educational General Core Flooding CF-E10 |

|

|---|---|

|

|

| Core Diameter | 1.5 inch |

| Maximum Core Length | 3.5 inch |

| Maximum Working Pressure | 400 bar |

| Maximum Confining Pressure | 400 bar |

| Maximum Working Temperature | 100°C |

| Hassler Core Holder | |

| Research General Core Flooding CF-E20 |

|

|---|---|

|

|

| Core Diameter | 1.5 inch |

| Maximum Core Length | 3.5 inch |

| Maximum Working Pressure | 400 bar |

| Maximum Confining Pressure | 400 bar |

| Maximum Working Temperature | 100°C |

| Back Pressure Regulator | 400 bar |

| Fluid Accumulators×3 | 500 CC |

| Hassler Core Holder | |

| Industrial General Core Flooding CF-E30 |

|

|---|---|

|

|

| Core Diameter | 1.5 inch |

| Maximum Core Length | 3.5 inch |

| Maximum Working Pressure | 600 bar |

| Maximum Confining Pressure | 600 bar |

| Maximum Working Temperature | 100°C |

| Back Pressure Regulator | 400 bar |

| Fluid Accumulators×3 | 700 CC |

| Hassler Core Holder | |

Related products

-

Spinning Drop IFT Measurement

Read moreThe designed Spinning Drop device (SD-ES10) is able to measure ultralow interfacial tension down to 10-5-5 mN/m. Ultra-low interfacial tension is utilized by special types of chemicals results in high oil recovery through IFT reduction and wettability alteration. These results help operators to develop and optimize emulsions and micro-emulsions.

Request for quote -

Sand Pack Core Flooding

Read moreThe sand pack system provides an alternative porous medium to perform EOR studies at reservoir conditions in terms of temperature and pressure. The sand pack is a tube, filled with calibrated sand with known grain geometry. This versatile device permits various EOR tests including water flooding, polymer injection, miscible and immiscible gas flooding. The sand pack system is an essential device for Petroleum Engineering laboratories as it does not require reservoir rock sample procurement & preparation.

Request for quote -

Benchtop Core Flooding

Read moreThe BCF-E10 evaluates and optimizes oil recovery, based on different injection protocols and fluid such as surfactant injection, polymer injection, etc… This device tolerates a maximum pressure of 400 bar for liquids under unsteady state conditions, at confining pressures of up to 400 bar. This device comprises one transfer vessel and a core holder, capable of different injection scenarios. In addition, the transfer vessel can be used for chemical or microbial flooding.

Request for quote -

HP-HT Pendant Drop IFT Measurement

Read moreThe pendant Drop Interfacial Tension system measures interfacial tension between liquid-gas and liquid-liquid interfaces using the pendant drop method as well as the contact angle between the liquid and solid interfaces at reservoir pressure and temperature of 400 bar and 100°C, respectively. This device utilizes two different manual pumps for the independent discharge of bulk fluid and drops fluid into the visual cell equipped with sapphire sight glasses. The device is also equipped with online image processing software that captures and analyses the images. The visual cell has external heaters placed inside the body of the cell to achieve homogenous heating.

Request for quote

Best offers

Customizing Orders Based On Customer Needs

Initial Setup & Installation

24x7 Support

Product Warranty & Guarantee

CIF Delivery

Know Us

The company provides new services based on state-of-art technologies, breaking into new markets, and eventually, stabilizing as a knowledge-based industrial group.

Read More