Products

- Core Preparation

- Routine Core Analysis

- Special Core Analysis

- Reservoir Stimulation

- EOR

- IFT Measurement

- Fluid Sampling

- PVT

- Pump

- Drilling Laboratory

- Petroleum Laboratory

- Aniline Point Measuring Device

- Cloud Point Measuring Device

- Copper Corrosion Measuring Device

- Distillation Apparatus for Petroleum Fluids

- Ductility of Bituminous Materials Measuring

- Flash Point Measuring Device

- Ostwald’s Viscometer

- Penetration of Bituminous & Lubricating Grease Materials Measuring Device

- Pour Point Measuring Device

- Reid Vapor Pressure Measuring Device

- Saybolt Viscometer

- Smoke Point Measuring Device

- Softening Point of Asphalts & Tar Pitches Measuring Device

- Fluid Laboratory

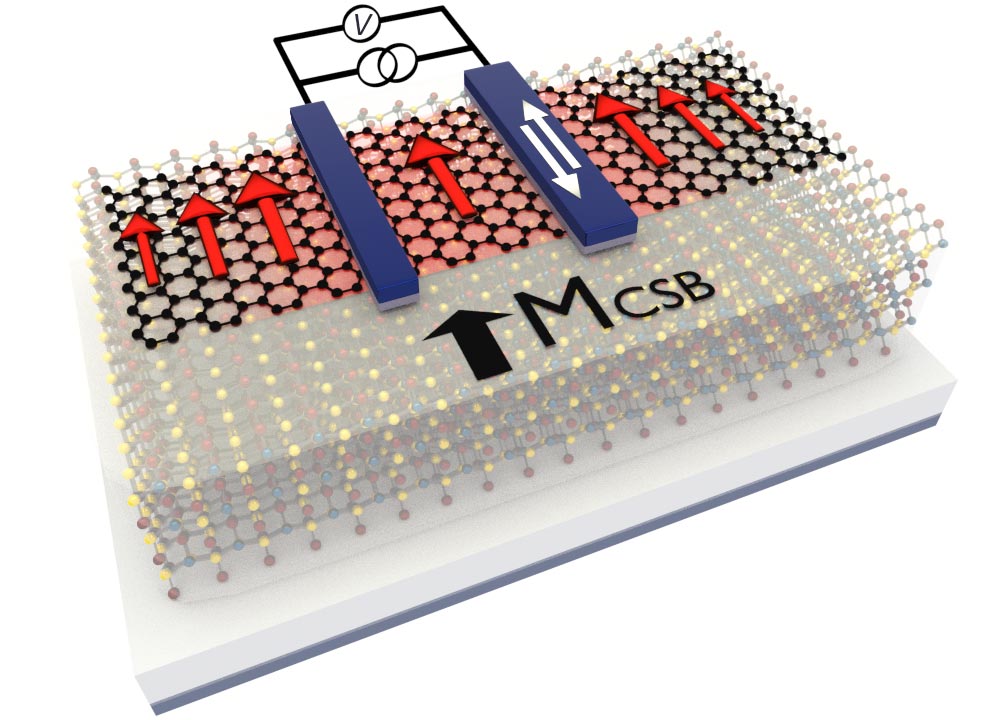

Our group is among the knowledge-based enterprise pioneers in petroleum industry.

Reid Vapor Pressure Measuring Device

The REID vapor Pressure Measuring device is an automated Reid Vapor pressure instrument that measures the vapor pressure of gasoline, volatile crude oil, and other volatile petroleum products. The RVP test is used in various quality control and R&D applications. RVP tests measure the potential impact of gasoline on engine performance and help benchmark fuels for various emission regulatory compliance programs.

| Educational Reid Vapor Pressure Measuring Device RVP-P10 |

|

|---|---|

|

|

| The Machine Includes a Water Bath | |

| Cylinders Made of Stainless Steel | |

| Electronic Temperature Control | |

| Static Color of the Body |

Related products

-

Sand Content Set

Read moreThe sand content kit is a simple, accurate, and inexpensive sieve analysis apparatus for determining the sand content of drilling muds. Sieve analysis is the preferred method for sand content determination because of the reliability of the test and the simplicity of the equipment. The volume of sand, including that of void spaces between grains, is usually measured and expressed as a percentage by the volume of the drilling fluid.

Request for quote -

Ostwald’s Viscometer

Read moreOstwald viscometer, also known as U-tube viscometer or capillary viscometer is a device used to measure the viscosity of the liquid with a known density. The method of determining viscosity with this instrument consists of measuring the time for a known volume of the liquid (the volume contained between the marks A and B) to flow through the capillary under the influence of gravity. The instrument must first be calibrated with materials of known viscosity such as pure (deionized) water. Knowing the value of the viscosity of one liquid, one can calculate the viscosity of another liquid.

Request for quote -

Cloud Point Measuring Device

Read moreCold flow properties, such as Cloud Point and Pour Point, indicate how petroleum products behave at low temperatures. The test specimen is cooled at a specified rate and measured periodically. The highest temperature at which a cloud is first detected at the bottom of the test jar is recorded as the cloud point. The lowest temperature at which movement of the specimen is detected is recorded as the pour point. This device is designed to provide a highly accurate cloud of temperatures of petroleum products during cooling.

Request for quote -

Flash Point Measuring Device

Read moreThis device is used to determine the flashpoint value of petroleum products, which is the temperature point at which the sample vaporizes to another composition state in the air that can be ignited. At that moment, the flashpoint apparatus can determine and measure the vapor pressure change in which this occurs, also known as the lowest limit of flammability. Therefore, vapor concentration can be determined by temperature. It is widely used in railway, aviation, electrical power, oil industries, and scientific research departments, etc.

Request for quote

Best offers

Customizing Orders Based On Customer Needs

Initial Setup & Installation

24x7 Support

Product Warranty & Guarantee

CIF Delivery

Know Us

The company provides new services based on state-of-art technologies, breaking into new markets, and eventually, stabilizing as a knowledge-based industrial group.

Read More