Products

- Core Preparation

- Routine Core Analysis

- Special Core Analysis

- Reservoir Stimulation

- EOR

- IFT Measurement

- Fluid Sampling

- PVT

- Pump

- Drilling Laboratory

- Petroleum Laboratory

- Aniline Point Measuring Device

- Cloud Point Measuring Device

- Copper Corrosion Measuring Device

- Distillation Apparatus for Petroleum Fluids

- Ductility of Bituminous Materials Measuring

- Flash Point Measuring Device

- Ostwald’s Viscometer

- Penetration of Bituminous & Lubricating Grease Materials Measuring Device

- Pour Point Measuring Device

- Reid Vapor Pressure Measuring Device

- Saybolt Viscometer

- Smoke Point Measuring Device

- Softening Point of Asphalts & Tar Pitches Measuring Device

- Fluid Laboratory

Our group is among the knowledge-based enterprise pioneers in petroleum industry.

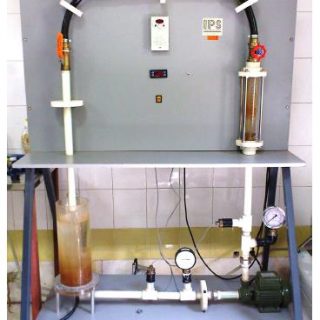

Osborne-Reynolds Device

The apparatus consists of a precision-bore glass pipe (test tube) held vertically in a large shroud. The shroud is open at the front and the inside surface is light-colored. This enables operators to see the flow. A fixed overflow pipe in the reservoir connects to a suitable drain. Moreover, the pipe is a valve that controls the flow rate through the pipe, without interrupting the flow. The base of the apparatus has adjustable bases for leveling before use.

| Educational Osborne-Reynolds Device OR-FM10 |

|

|---|---|

|

|

| The Main Reservoir of Plexiglas | Yes |

| Pipes and Fitting Made of Qualified PVC | Yes |

| Large Tank | Yes |

| NeedleValve | Yes |

Related products

-

Centrifugal Pump Machine

Read moreCentrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. Centrifugal Pumps have been designed especially for use in the food, dairy, beverage, pharmaceutical, and light chemical industries. Centrifugal pumps including multi-stage designs and those for high inlet pressure can handle most low viscosity applications. Centrifugal pumps can provide the most cost-effective solution.

Request for quote -

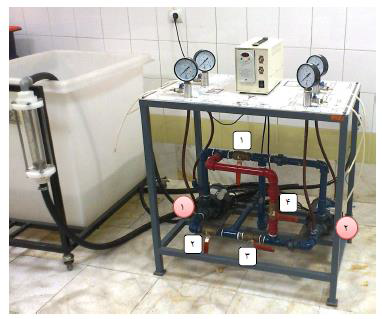

Series and Parallel Pump Apparatus

Read moreThe apparatus comprises two identical centrifugal pumps, together with two bearing-mounted motors driving each pump independently. The pumps draw water from the clear acrylic reservoir. The water travels through a series of valves to be delivered to a flow measurement device. The water then returns to the reservoir for re-use, keeping water use to a minimum. There are pressure gauges fitted in the intake and delivery pipes for the direct measurement and visible display of the inlet and outlet pressures of the pumps.

Request for quote -

Flow Meters

Read moreFlow meters are sophisticated measuring devices that employ a range of technologies designed to determine the volumetric flow rate or volume of a moving fluid, of either liquid or gas, in an open or closed conduit. The type of flow meter used will vary by application. Both gas and liquid flow can be measured in physical quantities of kind volumetric or mass flow rates, with units such as liters per second or kilograms per second, respectively.

Request for quote -

Venturi Meter

Read moreVenturi Meter is a device in which pressure energy is converted into kinetic energy and it is used for measuring the rate of flow of liquid through pipes. They are also instruments that use a converging section of the pipe to give an increase in the flow velocity and a corresponding pressure drop from which the flow rate can be determined. They have been in common use for many years, especially in the water supply industry, and work on the basic principle of Bernoulli’s Equation.

Request for quote

Best offers

Customizing Orders Based On Customer Needs

Initial Setup & Installation

24x7 Support

Product Warranty & Guarantee

CIF Delivery

Know Us

The company provides new services based on state-of-art technologies, breaking into new markets, and eventually, stabilizing as a knowledge-based industrial group.

Read More