Products

- Core Preparation

- Routine Core Analysis

- Special Core Analysis

- Reservoir Stimulation

- EOR

- IFT Measurement

- Fluid Sampling

- PVT

- Pump

- Drilling Laboratory

- Petroleum Laboratory

- Aniline Point Measuring Device

- Cloud Point Measuring Device

- Copper Corrosion Measuring Device

- Distillation Apparatus for Petroleum Fluids

- Ductility of Bituminous Materials Measuring

- Flash Point Measuring Device

- Ostwald’s Viscometer

- Penetration of Bituminous & Lubricating Grease Materials Measuring Device

- Pour Point Measuring Device

- Reid Vapor Pressure Measuring Device

- Saybolt Viscometer

- Smoke Point Measuring Device

- Softening Point of Asphalts & Tar Pitches Measuring Device

- Fluid Laboratory

Archives: Products

Showing 49–64 of 67 results

-

Helium Porosimeter at Confining Pressure

Read moreNormally, the porosity of the cores is measured without applying confining pressure on the samples. Although the confining pressure is not able to significantly affect the porosity value, it may lead to a huge deviation on the estimated value of the original oil in place. This device measures the porosity of the core samples while under confining pressure. This equipment can be used for grain density measurement at net confining stress. Moreover, Porosity is usually expressed as a percentage of the core plugs’ total volume.

Request for quote -

Helium Porosimeter

Read moreThe Helium gas Porosimeter determines the sample’s (1 inch or 1.5-inch diameter) grain and pore volume via an isothermal helium expansion and works based on Boyle’s and Charles’ law. Porosity is usually expressed as a percentage of the core plug’s total volume. The device tolerates an injection pressure of up to 10 bar (higher pressure is available upon request). Each sample matrix cup is interchangeable and is provided with stainless steel billets for calibration.

Request for quote -

Saturator and Gravimetric Porosimeter

Read moreSeveral methods have been developed to measure the porosity and pore volume of a sample. One method is called the fluid renaturation method. In this method, a clean and dried sample is weighted, saturated with a liquid of known density in a desiccator, and then reweighed. The weight change divided by the density of the fluid result in the pore volume.

Request for quote -

Liquid Permeability

Read moreThe liquid permeability device determines the absolute permeability of the plug-sized cores at ambient temperature using liquid (commonly used: water). In addition, this apparatus tolerates a confining pressure of up to 400 bar and is able to take into account the effect of upper layers on the permeability. This device is specifically designed to teach students the principles of liquid permeability efficiently.

Request for quote -

Gas Permeameter

Read moreThe gas permeability device is designed in a way that measures the permeability of plug-sized core samples with gas (air, nitrogen, …) at room temperature conditions while applying an overburden pressure of up to 20 bar using the steady-state method. This device is designed to determine the slip factor and Klingenberg permeability of the core plug samples.

Request for quote -

Electrical Properties Apparatus

Read moreThe electrical properties device is an instrument for ambient electrical resistivity measurement using core plug samples. The manual version of the device includes an ambient electrical properties cell for 1.5-inch cores up to 4 inches in length, a resistivity meter, and a brine resistance measurement dip cell. In addition, properties such as Formation Factor, Resistivity Index, Saturation Exponent n, and Cementation Factor m can be determined.

Request for quote -

HP Dual Pump

Read morePump consist of a general base unit which includes, Servo Motor, Gear Box, and HMI-based controlling unit. These pumps are designed for applications requiring accurate pulseless flow and pressure control for the delivery of fluids, solvents, and solutions. The dual pump is designed especially for continuous injection of fluids and solutions for pressure up to 400 bar based on the request with a maximum volume of 50 ccs. The advantage of the dual pump is the capability of using each barrel as an individual pump which changes a dual pump into two individual single pumps.

Request for quote -

HP Single Pump

Read morePump consist of a general base unit which includes, Servo Motor, Gear Box, and HMI-based controlling unit. These pumps are designed for applications requiring accurate pulseless flow and pressure control for the delivery of fluids, solvents, and solutions. This pump consists of a single injection unit with a maximum barrel volume of 250 ccs. Additionally, it is possible to inject the fluids at a constant flow and pressure.

Request for quote -

Gas-Oil Ratio Measurement

Read moreGOR plays an important role to assess the hydrocarbon volume and prepare the best production scenario. Moreover, the GOR device is designed in a way that makes it possible to flash pressurized liquids and measure the liberated gas at equilibrium conditions and dead liquid using calibrated collection device. The system is equipped with a manual 4 lit gasometers to measure the liberated gas with an accuracy of 1 cc while the pressure and temperature of the system are indicated.

Request for quote -

Piston Cylinder Type Shipping Bottle for Oil and Gas Sampling (Titanium)

Read moreThe high-pressure piston-cylinder type transfer vessels are commonly used in the oil and gas industries to transfer the liquid/gas samples into the laboratory for analysis. Additionally, a double-end piston-type cylinder was manufactured for the safe transportation of the reservoir fluid to the laboratory. The transfer vessel utilizes an internal low-friction floating piston to separate the driving fluid from the driven fluid. The cylinders are made of stainless steel 316 L which can also be manufactured using titanium upon the request of the client.

Request for quote -

Sand Pack Core Flooding

Read moreThe sand pack system provides an alternative porous medium to perform EOR studies at reservoir conditions in terms of temperature and pressure. The sand pack is a tube, filled with calibrated sand with known grain geometry. This versatile device permits various EOR tests including water flooding, polymer injection, miscible and immiscible gas flooding. The sand pack system is an essential device for Petroleum Engineering laboratories as it does not require reservoir rock sample procurement & preparation.

Request for quote -

Core Acidizing

Read moreThe core acidizing system is designed to make it possible to inject an acid solution into the rock sample at reservoir conditions to modify the natural permeability of the rock by dissolving some minerals present in the rock. Since the material is Hastelloy, it is possible to determine the efficiency of different HCI-HF formulations and study the effects of flow rate and temperature on the permeability of the core samples.

Request for quote -

Wettability Alteration Chamber

Read moreThe wettability alteration chamber is designed for the purpose of core wettability restoration prior to SCAL studies. The changes in wettability are obtained by subjecting the core to reservoir conditions of temperature and pressure for weeks. At this stage, a wettability transition may occur in the oil-invaded pores depending on the stability of the thin water films, located between the pore walls and the oil.

Request for quote -

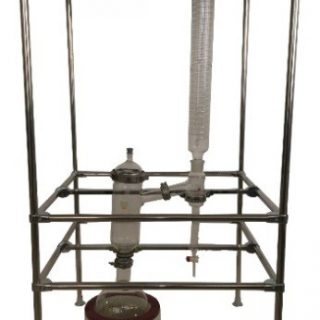

Dean Stark-Extractor

Read moreThe Dean-Stark apparatus is a piece of laboratory glassware used in synthetic chemistry to collect water (or occasionally other liquid) from a reactor. It is used in combination with a reflux condenser and a batch reactor for continuous removal of the water that is produced during a chemical reaction performed at reflux temperature. The dean stark extractor can also be used to determine the fluid saturation of core samples.

Request for quote -

Manual Core Saturation

Read moreThe manual saturator enables the end-user to obtain remarkable saturation of clean, dry core samples. The system is then evacuated by applying a high vacuum for a few hours. Finally, a manual pump is used to pressurize the system up to 300 bars. This pressure should be sustained for at least four hours to guarantee maximum core saturation. This is confirmed by a stable reading on the manometer.

Request for quote -

CO2-Solvent Core Cleaning

Read moreThe core cleaner is utilized to remove liquid phases (e.g. crude oil, drilling fluids, water…) from core plug samples. The principle consists of filling the gas-filled space in the core with solvent (e.g. toluene) by surrounding the core with a suitable solvent containing dissolved CO2 gas and applying sufficient hydraulic pressure. A number of repeated cycles are required to clean the core of hydrocarbons.

Request for quote

Best offers

Customizing Orders Based On Customer Needs

Initial Setup & Installation

24x7 Support

Product Warranty & Guarantee

CIF Delivery

Know Us

The company provides new services based on state-of-art technologies, breaking into new markets, and eventually, stabilizing as a knowledge-based industrial group.

Read More