Products

- Core Preparation

- Routine Core Analysis

- Special Core Analysis

- Reservoir Stimulation

- EOR

- IFT Measurement

- Fluid Sampling

- PVT

- Pump

- Drilling Laboratory

- Petroleum Laboratory

- Aniline Point Measuring Device

- Cloud Point Measuring Device

- Copper Corrosion Measuring Device

- Distillation Apparatus for Petroleum Fluids

- Ductility of Bituminous Materials Measuring

- Flash Point Measuring Device

- Ostwald’s Viscometer

- Penetration of Bituminous & Lubricating Grease Materials Measuring Device

- Pour Point Measuring Device

- Reid Vapor Pressure Measuring Device

- Saybolt Viscometer

- Smoke Point Measuring Device

- Softening Point of Asphalts & Tar Pitches Measuring Device

- Fluid Laboratory

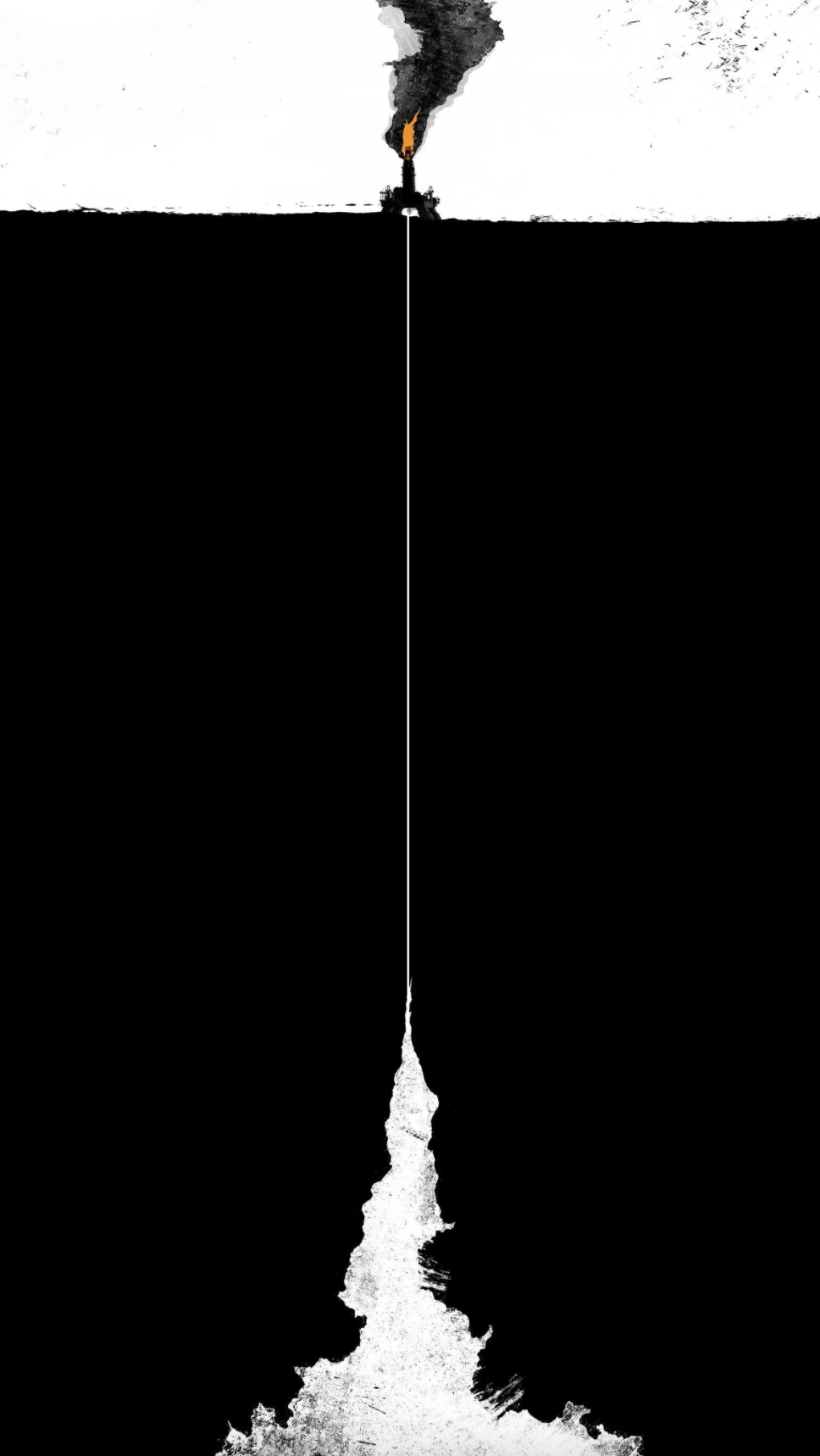

Our group is among the knowledge-based enterprise pioneers in petroleum industry.

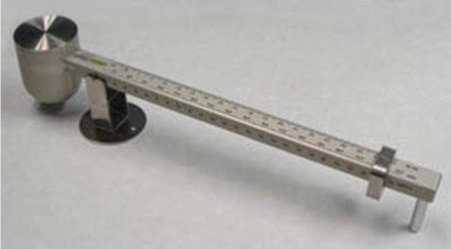

Mud Balance

Mud balance measures the density and specific gravity of drilling fluid and cement slurries. This apparatus is designed based on API-recommended standards. It is portable and can be carried to the rig to perform on-site measurements. It is one of the most sensitive and accurate field instruments available for determining the density or weight-per-unit-volume (specific gravity) of drilling fluids.

| Educational Mud Balance MB-D10 |

|

|---|---|

|

|

| Designed Based on API Recommended Practice 131 | |

| Stainless Steel Cup | |

| Special Gravity Measurement Range | 0.79 – 2.72 |

| Working Pressure | Ambient |

| Working Temperature | Ambient |

Related products

-

Saybolt Viscometer

Read moreThe Saybolt viscometer is a device that controls the heat of the fluid. Moreover, the viscosity is the time taken for the fluid to fill the container. These viscometers are most commonly used for fieldwork to measure the viscosity of oils, syrups, varnish, paints, and bitumen emulsions. The Saybolt viscometer can be found in different versions.

Request for quote -

Ostwald’s Viscometer

Read moreOstwald viscometer, also known as U-tube viscometer or capillary viscometer is a device used to measure the viscosity of the liquid with a known density. The method of determining viscosity with this instrument consists of measuring the time for a known volume of the liquid (the volume contained between the marks A and B) to flow through the capillary under the influence of gravity. The instrument must first be calibrated with materials of known viscosity such as pure (deionized) water. Knowing the value of the viscosity of one liquid, one can calculate the viscosity of another liquid.

Request for quote -

Mud Circulation Structure

Read moreThe device is used as a simulator of the mud circulation system. The drilling fluid circulating system is like a close loop electric circuit through which drilling fluid (i.e. mud) can travel from the surface to all the way downhole and back to its initial point (i.e. mud pit). The cuttings are then separated from the mud, which is then recycled.

Request for quote -

Retort Kit

Read moreThis apparatus simply measures the percentage of oil, water, and solid volume of the drilling fluid. The sample is first heated up to 550°C and the vapor is passed through a condenser. The condensates are collected to measure the oil and water volume of drilling. Knowledge of oil, water, and solid content is fundamental for proper control of mud properties when considering oil/water ratios, rheology, density, filtration, and salinity. Knowledge of solids in drilling fluids is essential for proper evaluation and viscosity control.

Request for quote

Best offers

Customizing Orders Based On Customer Needs

Initial Setup & Installation

24x7 Support

Product Warranty & Guarantee

CIF Delivery

Know Us

The company provides new services based on state-of-art technologies, breaking into new markets, and eventually, stabilizing as a knowledge-based industrial group.

Read More